A few weeks ago, we decided our starter motor needed rebuilding. We were very glad the problem arose when it did. Much better to do it here and now than to face the prospect of finding a shop, parts, etc while travelling. We hoped to have it in an out in a day or two, but the turnaround was almost a full week. This set back several items on our schedule and meant we would go at least another weekend without sailing Spartan. But these setbacks turned out to have several upsides.

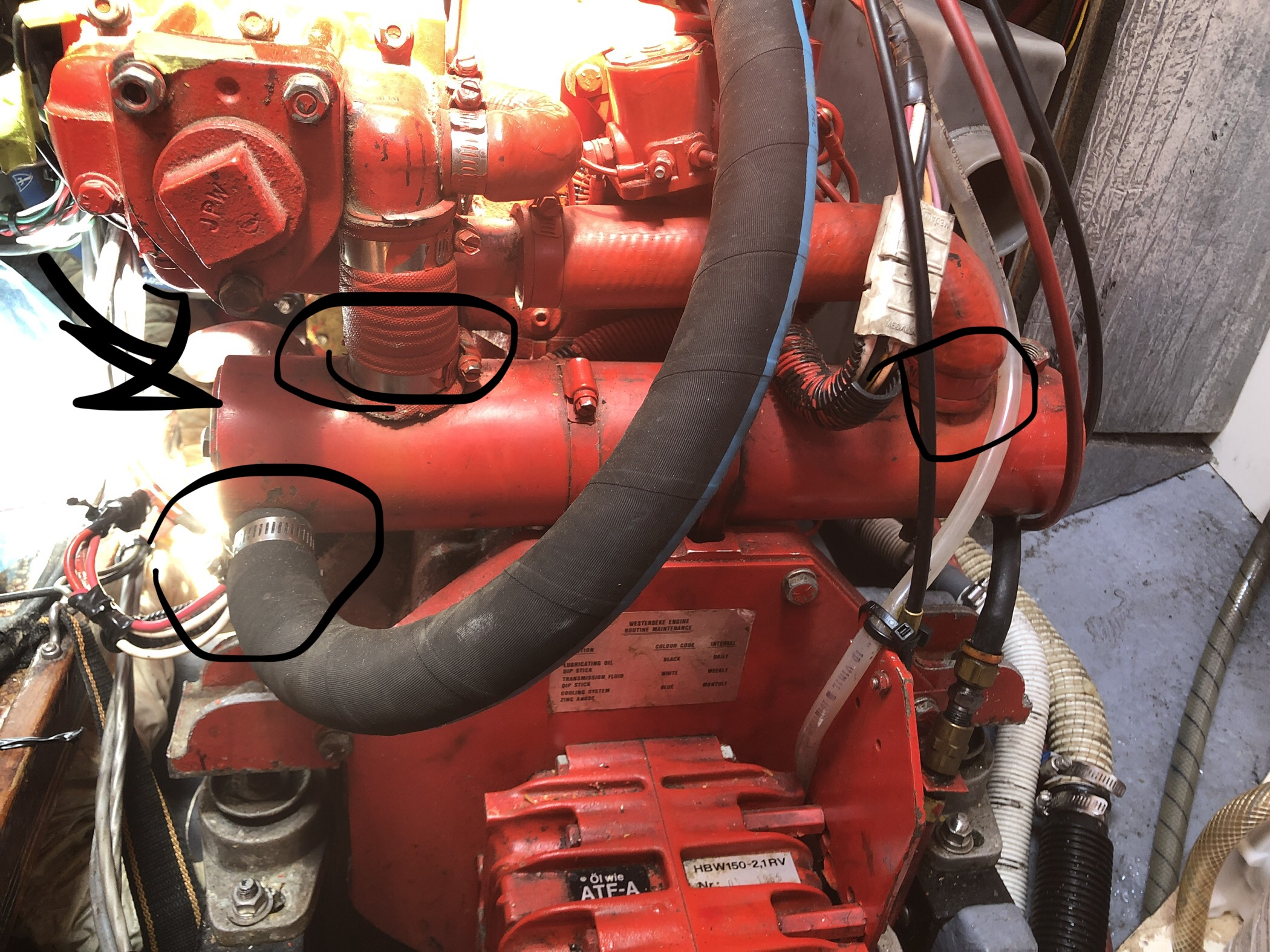

Since the boat was going to be out of commission anyways, it seemed like a good time to remove the heat exchanger and give it a good soaking in vinegar to remove any mineral build up. The unit was only slightly constricted, it turned out.

Removing the heat exchanger gave me an opportunity to get to know some other components better. With both the exchanger and the starter gone, I was left with several disconnected ground wires that were unlabelled, and plenty of time to trace and label them all. Some were easy to figure out, but others took hours. Now they are all neatly labelled at both ends.

That weekend, with our boat out of commission, a friend invited us to sail aboard their C&C 99. It was a great sail, and a great pleasure to spend time with them. If our boat had been in commission, we surely would have declined the invitation because we would have been sailing Spartan. So, being out of commission gave us a chance to experience sailing on a modern raceboat and deepen a friendship. Not a bad exchange!

At the same time, it gave me a chance to test our House batteries. Something had seemed amiss with them, but being at a dock with shore power, it was hard to notice. I wasn’t too worried because my plan was to replace them with batteries more appropriate for spending weeks away from shore power. Since I had the time, why not have a look? It turned out that the batteries were not holding a charge at all! A load test confirmed it: they were dead. And the batteries I wanted would, of course, take a week to arrive.

So, a second week with the boat in pieces, tools scattered throughout, schedules pushed back and unexpected free time on my hands. I spent the time upgrading a few things about my electrical system – installing connection busses, making it easier to secure and maintain the electrical system. I also reconfigured how the three different charging systems (shore power, solar power and alternator power) each connect to the batteries. The result should be better protection against premature battery failures. And it wouldn’t have happened if I hadn’t been forced to pause projects in progress.

Today, another set of circumstances has delayed my progress. My favourite chandlery (that means “boat parts store” btw) lent out their lug maker on Friday and is without one until at least Monday. These lug makers are expensive, heavy duty tools, and they are not easy to find. I only need the tool for about 10 minutes to complete my electrical projects. So, once again, I’m sitting on my hands in the middle of a project. Let’s see what good things come from this latest delay.

Another notch in the belt of patience!

LikeLike

Nice metaphor, Dad! I like that one.

LikeLike